Customized Hardware for Every Product

Discuss with us how we can fit the needs of your product line

Learn MoreInternational Advisory Service, Ltd. (IAS) is a custom hardware manufacturer that caters to the high-end, “Quality-Made,” leather goods and accessory industry. We help brands design, develop and implement custom hardware into their production line. We serve both the large scale global brands as well as the small manufacturers and utilize several manufacturing processes to meet quality expectations. By owning our factory we keep all production in-house, controlling the process from beginning to end, from the design process to full scale production. For over 75 years the top names in the industry have trusted IAS for their hardware needs.

Your Partner from Start to Finish

Hardware Design

Our team at IAS has partnered with companies in the Handbag and Accessory industry for decades providing our customers with experience-based service for the design and creation of custom hardware to fit their production line.

Fully Controlled Production

We own our manufacturing facility so that we can keep all production in-house. From the design process to full scale production, our customers depend on a high level of quality from us both in our service and finished products.

Volume Manufacturing

Volume large or small, we can handle it all. Whether you need to source in-stock buckles, swivel snaps, closures, locks and zippers, or custom manufacturing and prototyping, we will work with you to customize and integrate a design that works for your product.

Four Generations of Industry Experience

Founded in 1945, IAS is a family owned business dedicated to the development of hardware to the leather goods and accessory trade. It is our mission to provide customers with a level of expertise, service, and quality of product that is unmatched in the industry. Learn more about our history and how our capabilities have evolved over the years.

Our Core Services

Our Custom Hardware Process

Here’s a look at our process for custom hardware and how we handle all levels of development.

Step 1: Consultation

Our first step with customers is a consultation to learn more about the hardware needs for the products being developed. With decades of industry experience, we are sure to offer input regarding design and construction.

Step 2: Initial Designs

After our initial consultation we begin developing the initial designs of the hardware. Customers provide us with anything from simple sketches to CAD drawings or physical samples.

Step 3: 3D Samples

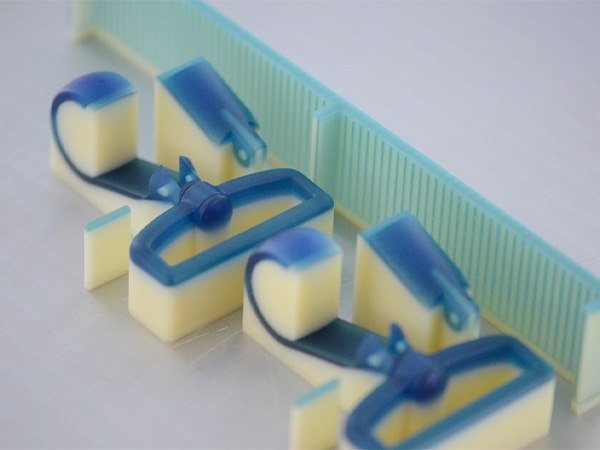

Whether you provide us with physical samples to match, or simple sketches, we use these to develop 3D drawings called STL files. We use these STL files to print plastic samples from our 3D printer in Massachusetts.

Step 4: Final Samples

After the initial plastic samples are approved, we move to final product sampling. These will be used as the pre-production samples from which the father mold is created.

Step 5: Production

Once the final samples are approved we move to production. Our factory has the capacity to handle both large and small scale production runs.

Step 6: Delivery

The hardware is packed and can be directly delivered anywhere in the world. We can also ship via ocean containers from our facility in Asia direct to our Massachusetts warehouse at no cost to you.